Les meilleures pinces de soudage

Hello, my friend, hello again; today we come together to talk about The Best Welding Clamps and hope the blog can help you.

Un ensemble de pinces de soudage peut fixer les matériaux pendant que vous soudez ou fournir une connexion à la terre pour le soudeur. Découvrez quel type est le mieux adapté à vos besoins.

Welding clamps are commonly used to hold material in place while welding, to hold two or more pieces together during the welding process, or to act as a ground connection for the electrical current running through the metal. Since welding clamps come in a variety of sizes, shapes, and styles, you can select the right-size clamps that are a good fit for your project. There’s also the choice of investing in welding table clamps, magnetic welding clamps, or even a full welding clamp set.

If you aren’t sure about which type of welding clamp to choose, or if you want a bit more information about welding clamps before making a final decision, it’s a good idea to take some time to research and learn more about the potential options. Keep reading to find out about key factors that differentiate welding clamps and consider the following list of some of the best welding clamps on the market, organized by category.

- MEILLEUR DANS L'ENSEMBLE : Hobart T-Style Brass Ground Clamp

- MEILLEUR RAPPORT QUALITÉ-PRIX : Lincoln Electric 300 Amp Ground Work Clamp

- BEST GROUND CLAMP: Gimiton 800 Amp Arc Welding Ground Clamp

- BEST 90-DEGREE: Betooll Cast Iron Welders Angle Clamp

- BEST FOR ROUND STOCK: Irwin Vise-Grip Locking Welding Clamp

- MEILLEURE COLLIER DE SERRAGE EN C : Tekton 11-Inch Locking C-Clamp

- MEILLEUR MAGNÉTIQUE : Baytory Upgrade Magnetic Welding Ground Clamp

- MEILLEUR USAGE MULTIPLE : MaxPower Thick Rail F Clamp

What to Consider When Choosing the Best Welding Clamp

When looking for the best welding clamps, consider the style, size, and contact area to find the right set for your next project. Before investing in any new product, first research how the tool is used and if it would be the most beneficial option for your budget and other needs.

Style

Welding clamps have a surprising variety of styles, including C-clamps, F-clamps, spring clamps, locking clamps, two-axis clamps, three-axis clamps, quick-action clamps, pipe clamps, and magnetic clamps.

- Pinces en C are very common in welding and woodworking. They have a C-shaped frame and a long bolt that gradually closes the distance between the fixed jaw and the movable jaw of the clamp when the user turns the handle. There are also locking C-clamps that combine the vise-grip-style locking handles with a rectangular C-shaped jaw.

- F-clamps are similar to C-clamps in that they rely on turning a bolt with a handle to close the jaws completely. However, F-clamps have a sliding arm that quickly closes the gap between the fixed jaw and movable jaw.

- Spring clamps rely on the tension of a spring to grip the workpieces. They cannot provide the same gripping power as a C-clamp or F-clamp, but this style is well suited for use as a welding ground clamp because it’s easy to fasten to the workpiece or move to a new location when necessary.

- Locking clamps tend to resemble a set of vise-grip pliers except they have much wider jaws that allow the clamp to open wide and firmly grip a range of materials. When the handles are squeezed together, the clamp locks in place. The grip can be further tightened with a screw located at the end of one handle. Release the clamp with the release trigger found on the opposite handle.

- Two-axis and three-axis welding clamps are designed for angled welding. With a two-axis clamp, two tubes or rods can be held at a precise angle while welding. A three-axis welding clamp allows users to weld a corner together by securing three tubes or rods during the welding process.

- Quick-action clamps or lever clamps resemble F-clamps, except instead of relying on a bolt to tighten the jaws, these clamps have a one-handed grip that just needs to be squeezed to slide the movable jaw up to the fixed jaw. Releasing the grip will lock the movable jaw in place, preventing the clamp from opening.

- Pipe clamps for welding are made to hold a cylindrical object instead of a flat or rectangular object. This unique shape is ideal for ensuring the smooth, rounded edges don’t slip or shift while working.

- Magnetic clamps differ from all other options on this list because they rely on magnetic force to hold the material in place. This makes it easier to hold materials at difficult angles without worrying about the clamp getting in the way of the weld.

Jaw Width

The size of clamps can vary depending on the style and purpose. For instance, two-axis corner clamps don’t have typical jaws, but they do come in a range of sizes to account for the differences in material thickness and construction. C-clamps, F-clamps, spring clamps, locking clamps, quick-action clamps, and pipe clamps typically have jaws that need to open wide enough to grip the project.

For those working with relatively small pieces of metal, like the metal tubes used to build lightweight furniture, it isn’t necessary to have a large jaw width. However, if the plan is to work with various materials in a range of sizes, then it’s better to consider clamps with wide jaws that can open to 3 or 4 inches in width.

Contact Area

Whether welding clamps are used to hold the pieces in position while welding or to ground a project, it’s important to use clamps with sufficient contact area. The contact area refers to how much of the welding clamp is in direct contact with the target material. The broader the contact area, the better the grip the clamps have on the piece.

Similarly, the larger the grounding welding clamp’s contact area, the more effective it will be at protecting the user from electric shock. Keep in mind that welders aren’t always working with flat or rectangular materials. For example, many automotive DIYers tend to use exhaust clamps versus welding because they may not know how to weld safely or they may not have suitable clamps for gripping the round pipes. Choose welding clamps that provide what’s needed to complete the next welding project.

Fonctionnalités supplémentaires

Welding clamps are relatively simple tools, so there aren’t a lot of additional features. Plus, a lot of extras could get in the way when welding. However, manufacturers may still decide to include some small extras like a floating swivel jaw pad, two-way spindle, or an anti-slip grip.

- Floating swivel jaw pads help to prevent the clamp from damaging the workpiece or slipping while in use. The jaw pads are designed to swivel slightly, allowing the pad to settle into the best position to grip the material without scratching the surface of the metal.

- Two-way spindles on corner welding clamps can swivel in order to change the size of the gap on the welding clamp. This makes it possible for the clamping block to work with pieces of varying thicknesses.

- Anti-slip grips are great for spring or locking clamps because they give the user additional control when they are attaching or removing the clamp from the workpiece.

Nos meilleurs choix

This list of the best welding clamps was selected based on size, contact area, jaw grips, style, and overall quality to help shoppers find the right clamps for their next welding project.

Meilleur dans l'ensemble

Hobart T-Style Brass Ground Clamp

Photo : amazon.com

One of the most important factors to consider when looking for a set of welding clamps is whether the clamp is needed to hold pieces in place or ground the electrical current from the welder. For those who want a grounding clamp, this one from Hobart uses a sturdy spring to fasten the clamp securely to the target material. However, it isn’t the best option for simply holding parts of the project in place.

Users attach grounding wires to the top of the clamp and then find a clean, dry place on the project to attach this spring grounding clamp. The rounded shape of the jaws makes it easier to fasten the clamp to rounded parts like pipes, and the textured grip at the mouth of the jaws helps to prevent the clamp from slipping. The jaws only open about 1.5 inches, but this is generally wide enough for a welding clamp that is intended for grounding instead of support.

Spécifications du produit

- Style: Spring grounding clamp

- Jaw width: 1,5 pouces

- Matériel: Laiton

Avantages

- Construction robuste

- Textured jaws for better grip

- Rounded shape to hold cylindrical pieces

- Rated to ground up to 400 amps

Inconvénients

- Jaws only open 1.5 inches

Get the Hobart welding clamp at Amazonas, Fourniture de tracteurs Co., ou Outils Acme.

Le meilleur rapport qualité/prix

Lincoln Electric 300 Amp Ground Work Clamp

Photo : amazon.com

Welding clamps that are made for welding can range in size, weight, and price, so for individuals that are just getting started, it may be best to opt for a more affordable grounding clamp like this one by Lincoln Electric. It’s made with an aluminum body and copper teeth that have a rounded shape in order to better grip flat, rectangular, or cylindrical materials.

The copper jaws are ideal for creating a good connection and ensuring that the welder is protected from electrical discharges. This clamp is lightweight and easy to use with one hand, and it is able to open to 2.5 inches.

Spécifications du produit

- Style: Spring grounding clamp

- Jaw width: 2,5 pouces

- Matériel: Aluminum and copper

Avantages

- Smooth, lightweight design

- Rounded teeth can hold flat, rectangular, or cylindrical pieces

- Copper jaws are highly effective at grounding electrical currents

- Prix abordable

Inconvénients

- Aluminum construction is less durable than others

Get the Lincoln Electric welding clamp at Amazonas, Sears, ou Le Dépôt d'Accueil.

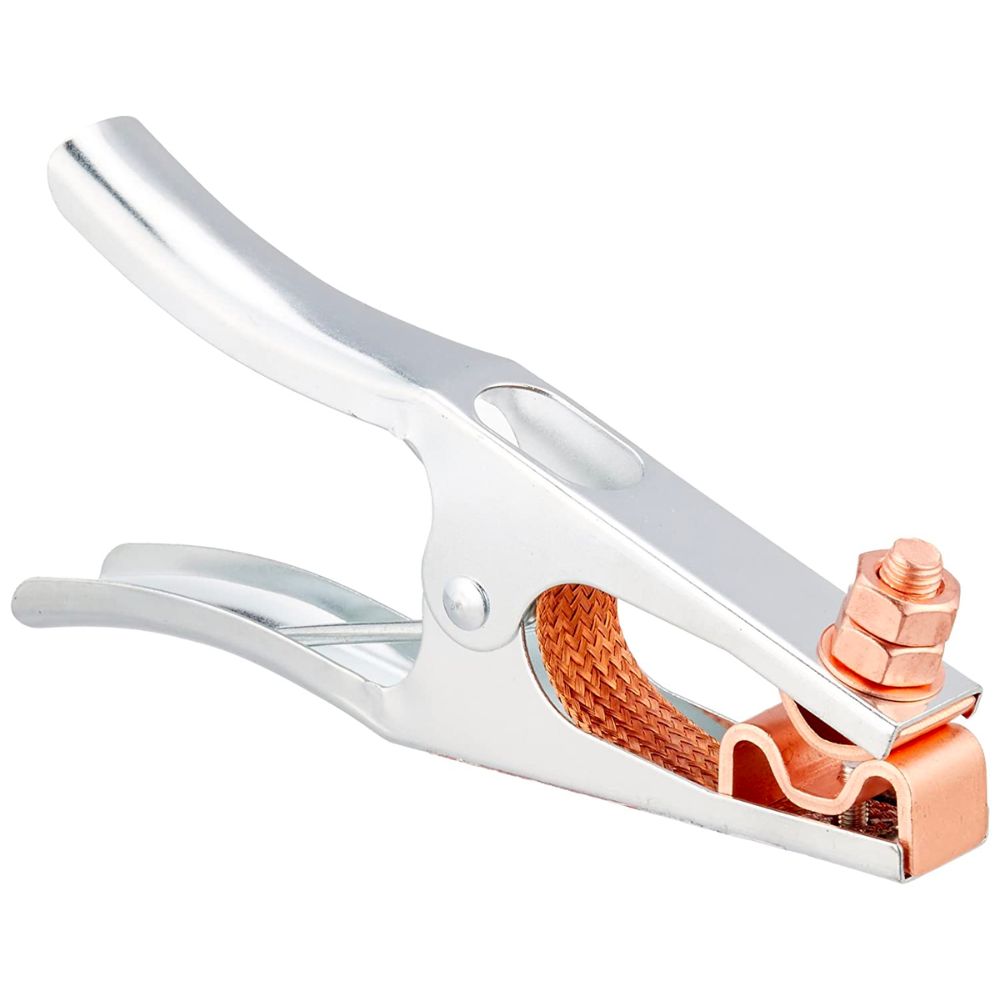

Best Ground Clamp

Gimiton 800 Amp Arc Welding Ground Clamp

Photo : amazon.com

It’s necessary to use a grounding clamp that has a maximum amp rating higher than the amperage rating of the companion grounding cable that’s being used. While most clamps are only made to handle about 300 to 400 amps, projects that require more effective protection can rely on this lightweight spring grounding clamp with a maximum amperage capacity of 800 amps.

The clamp is made with a mixture of iron and copper, making it easy for electricity to flow through the clamp and into the grounding wire. It features rounded jaws that can grip irregularly shaped items and material, while the strong spring helps to keep the clamp securely fastened to the project. However, the jaw width is not provided by the manufacturer, so it may be hard to figure out the maximum size of material it can clamp.

Spécifications du produit

- Style: Spring grounding clamp

- Jaw width: Non répertorié

- Matériel: Iron and copper

Avantages

- Rated to ground up to 800 amps

- Strong springs and rounded jaw improves grip

- Lightweight design is easy to use with 1 hand

- Copper jaws are highly effective at grounding electrical currents

Inconvénients

- Jaw width isn’t listed

Get the Gimiton welding clamp on Amazonas ou à Sears.

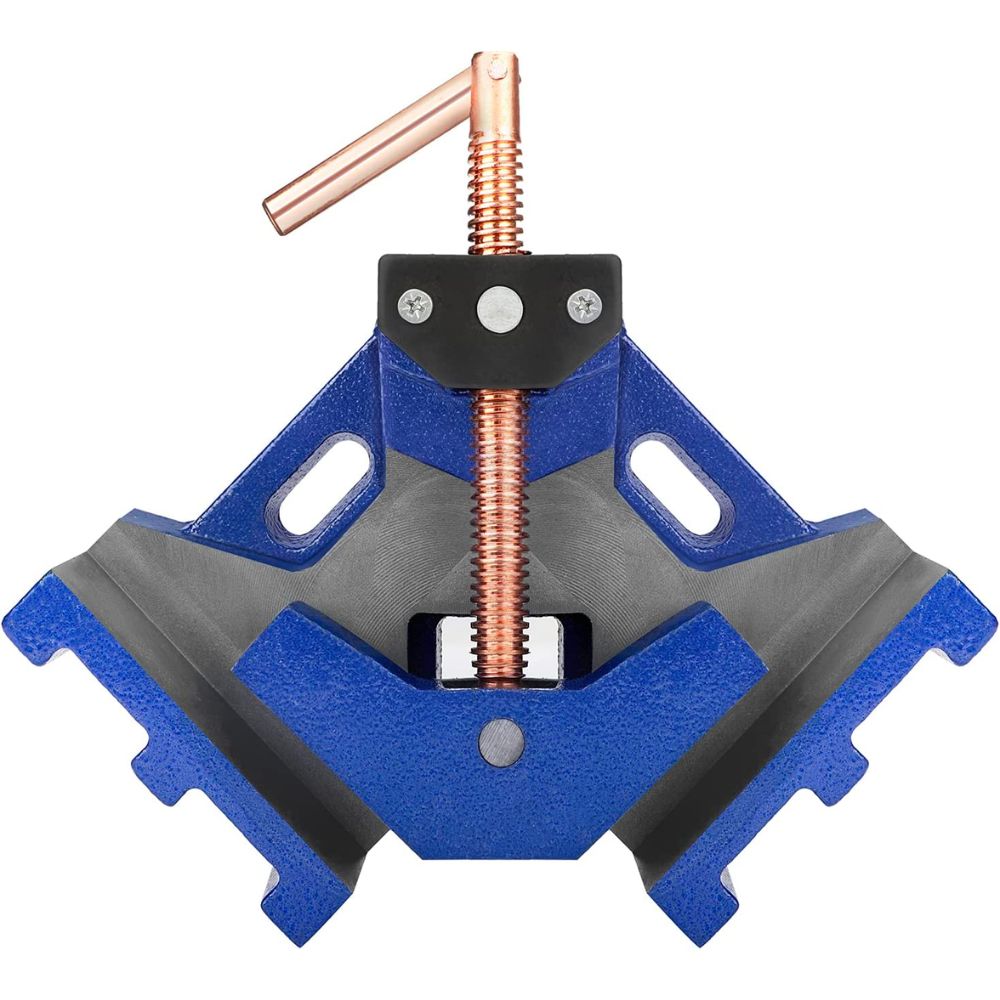

Best 90-degree

Betooll Cast Iron Welders Angle Clamp

Photo : amazon.com

Welding corners together can be a hassle when the welder doesn’t have the appropriate clamps to keep the pieces of the project from shifting or moving during the welding process. This two-axis clamp from Betooll is made from heavy-duty cast iron to help grip pieces of metal, like plates, angle iron, square tubing, and pipes. The clamp is designed to hold two pieces at a 90-degree angle without slipping or shifting.

This product comes with a two-way swivel-mounted spindle that can be used to adjust the position of the clamping block in order to work on pieces of different thicknesses. Despite this impressive adjustment capability, the clamp has a maximum jaw width of 2.5 inches, so it’s best used for holding relatively thin pieces of pipe or tubing.

Spécifications du produit

- Style: 2-axis clamp

- Jaw width: 2,5 pouces

- Matériel: Fonte

Avantages

- 2-way swivel-mounted spindle

- Heavy-duty cast-iron construction

- Ideal for holding plates, angle iron, and square tubing

- Holds workpieces at a 90-degree angle

Inconvénients

- Not effective for material wider than 2.5 inches

Get the Betooll welding clamp on Amazonas ou à Kmart.

Best for Round Stock

Irwin Vise-Grip Locking Welding Clamp

Photo : amazon.com

There are many clamps suitable for holding plates, angle iron, and square tubing, but it can be more difficult to find a versatile set of pipe clamps to ensure that round or cylindrical stock doesn’t slip or shift during a welding job. This set of locking pipe clamps features U-shaped jaws that are specifically designed to hold round or irregularly shaped pieces of metal.

The clamps have a vise-grip-style handle with an adjustment screw that can be used to increase or decrease the grip of the jaws. It also has a quick-release lever located in the opposite handle, so users can easily release the grip when the work is done. However, the unique shape of the jaws makes this tool a poor option for thin pieces of sheet metal and other flat or thin stock.

Spécifications du produit

- Style: Locking pipe clamps

- Jaw width: 2,75 pouces

- Matériel: Acier allié traité thermiquement

Avantages

- Specialized teeth for gripping round stock

- Adjust grip pressure with the adjustment screw

- High-grade heat-treated alloy-steel construction

- Quick-release lever for simple, 1-handed use

Inconvénients

- Not suitable for gripping flat or thin stock

Get the Irwin welding clamp on Amazonas, Toolbarn.com, ou Zoro.